EastMed's Hot Spot: Zohr's Development

Eni's parallel-development method has enabled it to smash records at its mega-giant Zohr gas project.

The nearly complete control room at Eni's Zohr onshore facility on the Mediterranean coast west of Port Said has all the appearances of a mission control centre for a space programme. Semi-circular consoles are arranged in front of a giant screen high up on the wall ahead. Beneath the tiled floor, workers are feeding in and connecting lines of cable—some of the 1,600 kilometres that have been installed thus far at the plant.

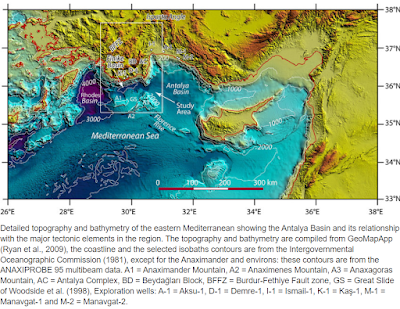

This building, smelling of newly applied paint and cement, will soon take charge of every single aspect of the Zohr project. It will link by radio to an unmanned control platform 85km offshore, which in turn, by means of fibre-optic cables and hydraulic and electrical lines, will set the flow of gas at the Zohr field, which is 190km north of Port Said. The Eni staff like to point out that the control platform lies 160km from the field, "the distance from Milan to Genoa".

The story of how Eni discovered a previously unknown carbonate layer under the Mediterranean in August 2015 has been told many times. Much less has been said about the process that enabled Eni to smash all existing records by bringing Zohr on stream in less than two and a half years.

The magnitude of the discovery (gas in place of at least 30 trillion cubic feet) in the Shorouk Block was obvious as soon as exploration wells had been drilled. Without delay, both Eni and the Egyptian government agreed that the find should be developed as quickly as possible. The whole project would be operated by the Belayim Petroleum Company (Petrobel), a joint venture between Eni and Egyptian General Petroleum Corporation. An execution strategy was set, leveraging the experience of Petrobel in Egypt and with the cooperation of major contractors Petrojet, Enppi, Saipem and PMS. This close coordination from day one, Eni executives say, contributed to the success of the Zohr project.

Dual-exploration model

A preliminary development plan was given to the Egyptian authorities in the month following the discovery and a final version submitted in November. An appraisal well was drilled in January 2016. Such was the confidence of the two parties in the project that a final investment decision was taken in February. A process that could be expected to take a year or more was completed in just six months. Even before FID, the longest-delivery items had been ordered—most of the tenders for critical equipment were issued in December 2015 and the 26-inch field-to-shore pipeline in January 2016.

At this point, Eni brought into play what it calls its "dual-exploration model", which was adopted in 2013 and involves exploration, appraisal and development phases running in parallel. In essence, this meant that all elements in the Zohr project, offshore and onshore, were started at about the same time. For example, around 40 vessels were involved in offshore installation and drilling at the Zohr field for a whole year—whereas normally installation campaigns are carried out only for a few months at a time. In July 2016, Italy's Saipem was contracted to install the export pipeline, along with two smaller service lines, from Zohr to the site of the onshore plant. In June 2017, Egypt's Petrojet completed the offshore platform construction. Eni's plan is to drill 20 wells; six have been completed thus far.

Meanwhile, back in April 2016 the Egyptian authorities designated an open area of land for Zohr's onshore facilities. This has the sea to the north and Lake Manzala, a shallow, brackish lagoon to the south. The ground is very difficult to build on, with a thin layer of sand on top and soft clay beneath. Before any construction can begin, tubular wire frames are driven deep into the ground and filled with cement. A concrete foundation base is then built over the top. All around the site one sees tufts of thick wire from the tops of the piles sticking through the concrete, awaiting the construction of a new facility.

Early-production plant

Towards the end of 2017, work on an early-production gas-processing train at the eastern end of the site was completed, ahead of Zohr coming on stream in December. The train has its own utilities—again to enable production to begin even when the bulk of the plant was still under construction. Large grey pipes transport the processed gas to a link-up point within the Zohr compound to the distribution network of the Egyptian Natural Gas Company.

Eni's parallel method of working is clearly visible at the Zohr onshore site, where the emphasis is definitely not on the conventional way of finishing one phase of a project before beginning the next one. For example, the plan is for the plant to have eight gas-processing trains, each with 350m cf/d capacity. With the early-production facility already in operation, construction of four more trains is under way, at differing stages of completion. Site preparation for more trains is underway.

In the meantime, work is nearing completion on various other facilities, including a central power plant with three turbines—the foundations for a fourth are ready. Naturally enough, the facility will run on gas from the Zohr field. Work is close to completion on the first sulphur-removal plant, a tangle of yellow, blue and green pipes. It was constructed in Italy in 50 modules and assembled on site.

New investors

The rapid pace of development—the year-long exploration programme at the field and the simultaneous upstream-downstream work—involved huge expense. To help cover the costs, Eni adopted another aspect of its dual-exploration model: benefiting from early monetisation by the sale of minority stakes, while maintaining the operatorship. In November 2016, BP acquired a 10% stake in Zohr. Rosneft took a 30% share the following month.

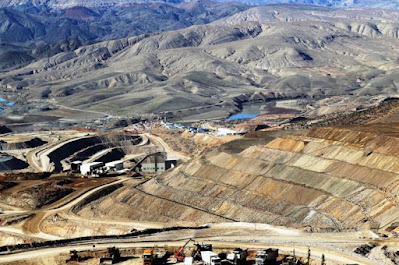

The whole onshore site is vast: 2.7km in length and 700 metres wide. Today, the fenced-off operating area, where the early-production train is located, is relatively quiet and calm. But the rest of the site is abuzz with the sounds of cranes, trucks and diggers, throwing up clouds of dust. Daily, between 11,000 and 13,000 people are working on the site, not just on gas facilities but also on a mosque, offices and other amenities. Work carries on into the night, but then there's a six-hour break when inspections are carried out, including the x-raying of every piece of welding to ensure the quality.

Eni is confident that the frenetic but carefully monitored pace of construction will ensure that the project meets it output targets: 350m cf/d in the current phase, rising to 1bn cf/d by the middle of this year and 2.7bn cf/d by the end of 2019. There's no doubt that this phenomenal progress that began with an offshore discovery in 2015 has been achieved in large part by the desire of the Egyptian authorities to bring as much natural gas on line as fast as possible to meet rising demand and end liquefied natural gas imports. Eni's chief executive Claudio Descalzi has spoken of the "all-important contributions" of the "whole Egyptian petroleum sector which provided full support to achieve the Zohr project in record time".

Eni was also in a strong position because of its deep roots in Egypt-having operated there since the 1950s. Egypt, unlike other potential gas producers in the Eastern Mediterranean, has a well-established gas distribution infrastructure. Nevertheless, Eni's parallel-development method which, as one executive said, "breaks all the normal ways of doing things", was also key. It's a method that other IOCs may well consider adopting in the future.

The nearly complete control room at Eni's Zohr onshore facility on the Mediterranean coast west of Port Said has all the appearances of a mission control centre for a space programme. Semi-circular consoles are arranged in front of a giant screen high up on the wall ahead. Beneath the tiled floor, workers are feeding in and connecting lines of cable—some of the 1,600 kilometres that have been installed thus far at the plant.

This building, smelling of newly applied paint and cement, will soon take charge of every single aspect of the Zohr project. It will link by radio to an unmanned control platform 85km offshore, which in turn, by means of fibre-optic cables and hydraulic and electrical lines, will set the flow of gas at the Zohr field, which is 190km north of Port Said. The Eni staff like to point out that the control platform lies 160km from the field, "the distance from Milan to Genoa".

The story of how Eni discovered a previously unknown carbonate layer under the Mediterranean in August 2015 has been told many times. Much less has been said about the process that enabled Eni to smash all existing records by bringing Zohr on stream in less than two and a half years.

The magnitude of the discovery (gas in place of at least 30 trillion cubic feet) in the Shorouk Block was obvious as soon as exploration wells had been drilled. Without delay, both Eni and the Egyptian government agreed that the find should be developed as quickly as possible. The whole project would be operated by the Belayim Petroleum Company (Petrobel), a joint venture between Eni and Egyptian General Petroleum Corporation. An execution strategy was set, leveraging the experience of Petrobel in Egypt and with the cooperation of major contractors Petrojet, Enppi, Saipem and PMS. This close coordination from day one, Eni executives say, contributed to the success of the Zohr project.

Dual-exploration model

A preliminary development plan was given to the Egyptian authorities in the month following the discovery and a final version submitted in November. An appraisal well was drilled in January 2016. Such was the confidence of the two parties in the project that a final investment decision was taken in February. A process that could be expected to take a year or more was completed in just six months. Even before FID, the longest-delivery items had been ordered—most of the tenders for critical equipment were issued in December 2015 and the 26-inch field-to-shore pipeline in January 2016.

At this point, Eni brought into play what it calls its "dual-exploration model", which was adopted in 2013 and involves exploration, appraisal and development phases running in parallel. In essence, this meant that all elements in the Zohr project, offshore and onshore, were started at about the same time. For example, around 40 vessels were involved in offshore installation and drilling at the Zohr field for a whole year—whereas normally installation campaigns are carried out only for a few months at a time. In July 2016, Italy's Saipem was contracted to install the export pipeline, along with two smaller service lines, from Zohr to the site of the onshore plant. In June 2017, Egypt's Petrojet completed the offshore platform construction. Eni's plan is to drill 20 wells; six have been completed thus far.

Meanwhile, back in April 2016 the Egyptian authorities designated an open area of land for Zohr's onshore facilities. This has the sea to the north and Lake Manzala, a shallow, brackish lagoon to the south. The ground is very difficult to build on, with a thin layer of sand on top and soft clay beneath. Before any construction can begin, tubular wire frames are driven deep into the ground and filled with cement. A concrete foundation base is then built over the top. All around the site one sees tufts of thick wire from the tops of the piles sticking through the concrete, awaiting the construction of a new facility.

Early-production plant

Towards the end of 2017, work on an early-production gas-processing train at the eastern end of the site was completed, ahead of Zohr coming on stream in December. The train has its own utilities—again to enable production to begin even when the bulk of the plant was still under construction. Large grey pipes transport the processed gas to a link-up point within the Zohr compound to the distribution network of the Egyptian Natural Gas Company.

Eni's parallel method of working is clearly visible at the Zohr onshore site, where the emphasis is definitely not on the conventional way of finishing one phase of a project before beginning the next one. For example, the plan is for the plant to have eight gas-processing trains, each with 350m cf/d capacity. With the early-production facility already in operation, construction of four more trains is under way, at differing stages of completion. Site preparation for more trains is underway.

In the meantime, work is nearing completion on various other facilities, including a central power plant with three turbines—the foundations for a fourth are ready. Naturally enough, the facility will run on gas from the Zohr field. Work is close to completion on the first sulphur-removal plant, a tangle of yellow, blue and green pipes. It was constructed in Italy in 50 modules and assembled on site.

New investors

The rapid pace of development—the year-long exploration programme at the field and the simultaneous upstream-downstream work—involved huge expense. To help cover the costs, Eni adopted another aspect of its dual-exploration model: benefiting from early monetisation by the sale of minority stakes, while maintaining the operatorship. In November 2016, BP acquired a 10% stake in Zohr. Rosneft took a 30% share the following month.

The whole onshore site is vast: 2.7km in length and 700 metres wide. Today, the fenced-off operating area, where the early-production train is located, is relatively quiet and calm. But the rest of the site is abuzz with the sounds of cranes, trucks and diggers, throwing up clouds of dust. Daily, between 11,000 and 13,000 people are working on the site, not just on gas facilities but also on a mosque, offices and other amenities. Work carries on into the night, but then there's a six-hour break when inspections are carried out, including the x-raying of every piece of welding to ensure the quality.

Eni is confident that the frenetic but carefully monitored pace of construction will ensure that the project meets it output targets: 350m cf/d in the current phase, rising to 1bn cf/d by the middle of this year and 2.7bn cf/d by the end of 2019. There's no doubt that this phenomenal progress that began with an offshore discovery in 2015 has been achieved in large part by the desire of the Egyptian authorities to bring as much natural gas on line as fast as possible to meet rising demand and end liquefied natural gas imports. Eni's chief executive Claudio Descalzi has spoken of the "all-important contributions" of the "whole Egyptian petroleum sector which provided full support to achieve the Zohr project in record time".

Eni was also in a strong position because of its deep roots in Egypt-having operated there since the 1950s. Egypt, unlike other potential gas producers in the Eastern Mediterranean, has a well-established gas distribution infrastructure. Nevertheless, Eni's parallel-development method which, as one executive said, "breaks all the normal ways of doing things", was also key. It's a method that other IOCs may well consider adopting in the future.

Comments

Post a Comment